Understanding How CAD and Mechanical Design Software Support Engineering Mechanical design software is a type of computer-aided design (CAD) software specifically designed for mechanical design purposes. This software is regularly used in industries such as automotive engineering and aerospace, where components benefit from the design and optimization processes that CAD facilitates, often making it easier to test performance under specific conditions.

Opinions expressed by Entrepreneur contributors are their own.

You're reading Entrepreneur Asia Pacific, an international franchise of Entrepreneur Media.

In the past, engineers, architects, and manufacturers designed components using physical blueprints and lacked advanced methods for optimizing systems before they were manufactured. While these methods may have once been sufficient, they can no longer keep pace with today's heightened demand for speed, precision, and innovation, necessitating the mechanical design software that engineers and other professionals use today.

Mechanical design software enables professionals to create, simulate, and optimize complex mechanical systems while allowing for precise adjustments. By using this software, engineers can reduce errors, accelerate product development, and bring novel ideas to reality more quickly.

What Is Mechanical Design Software?

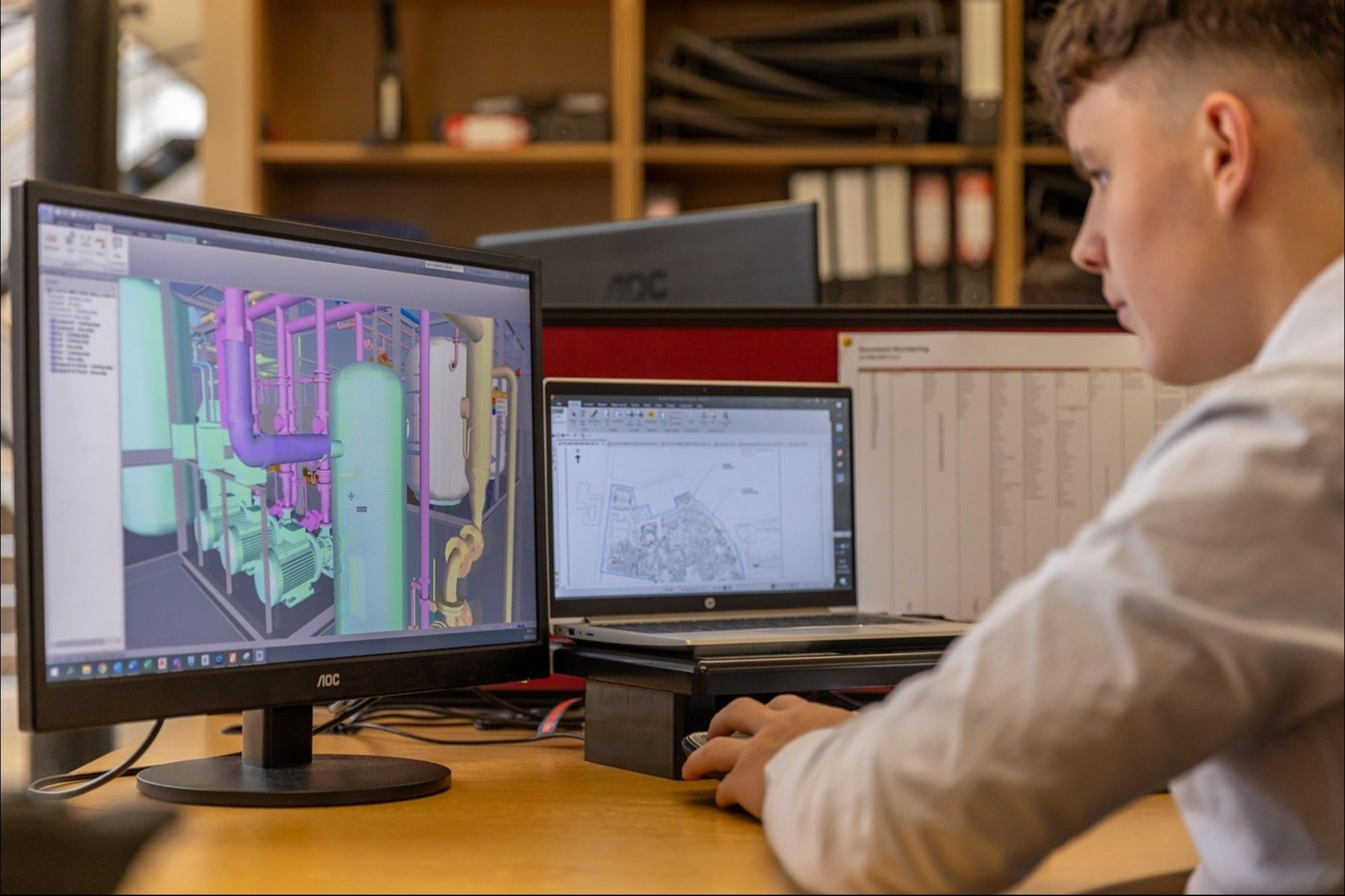

Mechanical design software is a type of computer-aided design (CAD) software specifically designed for mechanical design purposes. This software is regularly used in industries such as automotive engineering and aerospace, where components benefit from the design and optimization processes that CAD facilitates, often making it easier to test performance under specific conditions.

CAD can be challenging to understand without firsthand experience; however, it essentially allows users to design, analyze, document, and manufacture products tailored to the specific needs of a given project. Part of what makes this software so valuable is that it hosts most, if not all, of these tools in one place, making it compact and relatively convenient.

The Many Benefits of CAD

CAD tools have revolutionized the way engineers approach modern design, in part because they enable professionals to conduct extensive testing on factors such as stress points, thermal effects, and mechanical movement before creating physical prototypes. Doing this modeling beforehand helps reduce waste in the manufacturing process, as prototypes are not needed to test all the same factors that can be simulated digitally.

Mechanical design software also enables engineers to create and refine highly accurate 3D models, thereby reducing the risk of costly design flaws and other errors that may only become apparent during production. These processes are further enhanced through collaboration, as CAD enables teams across different locations to work together on the same project by sharing models and updates in real-time.

One of the more noticeable upgrades mechanical design software provides is automation. Working on repetitive design tasks and integration often consumes substantial amounts of time and resources, making their automation in manufacturing processes helpful in reducing costs.

All of these benefits combine to improve a final product's overall quality; as Coursera explains, "CAD supports quick prototyping and direct design transfer, in which the model seamlessly transfers directly to the manufacturing equipment. This efficient design transfer can help cut waste, increase accuracy, and reduce errors."

The Expanding Utility of Mechanical Design Software

Although the technology is now over 40 years old, CAD and mechanical design software continue to offer significant benefits in manufacturing and production. Actively developing applications in AI and ML, for example, could expand the capabilities of design engineering software far beyond its current limits.

Given its numerous engineering applications, CAD is often used for testing and designing complex machines; however, the technology has also recently seen some innovative uses. CAD has become popular in graphic design, game design, and even fashion design, expanding the boundaries of an already impressive technology.

FAQ

Q: What is mechanical design software?

A: Mechanical design software is a form of CAD that helps engineers create, test, and optimize 3D models of mechanical components and systems.

Q: How does product development benefit from mechanical design software?

A: This software reduces errors, accelerates prototyping, improves collaboration, and allows virtual testing of designs to ensure performance is up to standard.

Q: Which industries use mechanical design software the most?

A: Industries that work with and create complex systems benefit from this software the most. These include aerospace, automotive, and robotics industries.